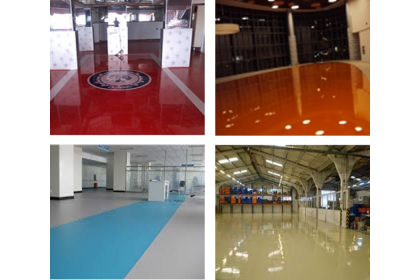

At Hedef Spor, we provide PVC flooring solutions tailored for sports areas and multi-purpose surfaces. Combining aesthetics with functionality, PVC floors are highly durable against impact and abrasion, offering long-lasting performance. With their non-slip surface, shock-absorbing structure, and easy-to-clean properties, they are ideal for gyms, fitness centers, schools, and healthcare facilities.

Our expert team carefully analyzes your flooring needs and ensures precise application with attention to detail. With a variety of thickness and color options, we enhance your space both visually and functionally. Thanks to their antibacterial features, PVC floors provide a hygienic environment and are perfectly suited for high-traffic areas.

Choose Hedef Spor’s PVC flooring service for quality, reliability, and aesthetic appeal!

Conductive PVC Flooring System

Our conductive PVC flooring system, specifically designed for areas where static electricity must be controlled, offers high performance and safety. Available in tile or roll form, the system ensures conductivity through copper strips embedded in the sublayer. Additionally, a semi-gloss, three-component, epoxy-based conductive coating alternative is also available.

Key Features

High chemical and mechanical resistance

Hard, durable, and long-lasting surface

Water-based composition: low VOC emission, non-flammable

Applicable on damp surfaces

Semi-gloss, non-slip finish

Easy to clean, dust-free, bacteria-resistant

High UV resistance

Free from substances harmful to human health

Areas of Use

Operating Rooms

Laboratories

Computer and Server Rooms

Electronics Manufacturing Lines

TV Studios

Production and Storage Areas with High Electrical Loads

This system provides a safe, hygienic, and long-lasting flooring solution in areas where preventing risks from static electricity is critical.

Flexible PVC Flooring Systems

Flexible PVC flooring systems are specially developed flooring solutions for indoor spaces where hygiene, durability, and aesthetics are key priorities. The application process begins with meticulous surface preparation and continues with professional installation steps to achieve a seamless and long-lasting finish.

Application Steps

The surface is completely cleaned of dust, oil, paint, and other residues.

Minor cracks and gaps are repaired, and the surface is leveled using a sanding machine.

A suitable primer is applied to prepare the surface for adhesive.

Adhesive is evenly spread with a fine-notched trowel.

PVC covering is laid over the adhesive once it reaches the correct consistency.

The material is fixed by removing air bubbles.

Joints between pieces are opened with a special grooving knife.

A hot welding process is applied to the joints, creating a seamless and hygienic surface.

Areas of Use

Flexible PVC flooring systems are widely used in the following indoor spaces:

Healthcare Facilities: Hospitals, health centers, clinics, laboratories, operating rooms, intensive care units, X-ray rooms

Educational Institutions: Schools, kindergartens, dormitories, nurseries

Commercial and Public Spaces: Offices, government buildings, airports, shopping centers, supermarkets

Social Areas: Hotels, restaurants, cinemas, theaters, conference and concert halls

Industrial Areas: Factory offices, cafeterias

Thanks to its hygienic structure, easy-to-clean surface, and aesthetic appeal, this system offers ideal solutions for high-traffic indoor environments.

Homogeneous PVC Floor Covering

The most important feature of PVC flooring systems is their successful combination of aesthetics and functionality. In addition to offering a wide range of sizes and patterns, they are highly practical, antibacterial, hygienic, durable, and economical. They are produced in accordance with all quality certification programs. The surface of PVC flooring is manufactured using a special PUR (Polyurethane Reinforced) technique, which ensures a healthy environment by preventing bacterial growth.

PVC flooring offers numerous advantages. It is resistant to wear and environmental conditions. It is extremely hygienic and does not harbor bacteria.

Application Process

The substrate must be thoroughly cleaned of dust, cracks, gaps, oil, and paint residues. A sanding machine is used to absorb fine dust. Then, a primer is applied to prepare the surface for the adhesive. The adhesive is spread with a fine-notched trowel. Once it reaches the proper consistency, the PVC material is laid onto the adhesive. Air bubbles are removed by pressing. Joints between pieces are opened with a grooving knife, and hot welding is applied with a welding machine to form a seamless surface.

Areas of Use

PVC flooring systems are used in the following indoor spaces:

Hospitals, health centers, dispensaries, laboratories

Pharmacies, schools, kindergartens, dormitories, nurseries

Offices, homes, government buildings

Stores, supermarkets

Hotels, restaurants, indoor sports halls

Cinemas and theaters

Conference, concert, and convention halls

Shopping centers, factory management offices

Airports, cafeterias, operating rooms

X-ray rooms, corridors, intensive care units